- Throttle and Collective Modifications -

|

Here is the finished collective and throttle. What about the pilot to copilot throttle linkage? The stock linkage was big and ungainly, it hit the fiberglass bottom tub and it was a lot of overkill for turning a potentiometer. I sawed it off. |

|

Realizing that future instructors or copilots might not look favorably upon this, I figured I'd better come up with an alternative, so here is what I used instead. I machined two small pulleys, pinned them on the pilot and copilot throttle shafts and got some 1/32" stainless steel cable. Also, note where I enlarged the inside end of the pilot's throttle shaft to 1/4" ID to receive the throttle potientiometer shaft. |

|

I opened up the area through the collective cross-tube, installed the throttle shafts and pulleys, then connected the two pulleys together with the 1/32" cable. Here is the view of the left end of the collective. |

|

This is the right end of the collective. Pretty simple, very smooth. The 1/32" stainless steel cable is about 120 lb-test, more than capable of transmitting the small amount of torque required to turn the throttle potentiometer. |

|

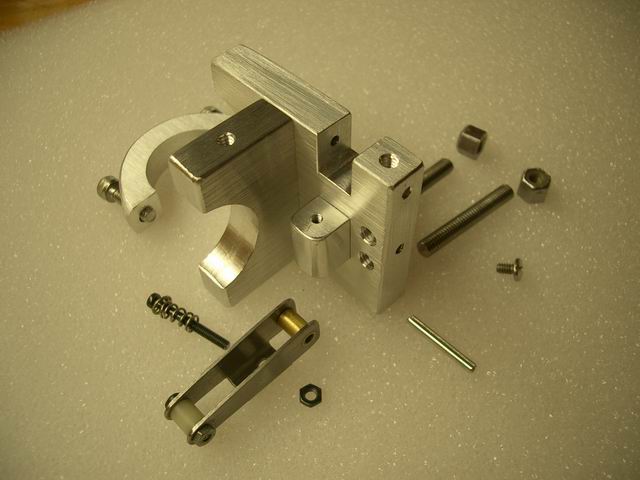

Here are some of the parts I machined from 3/8" aluminum to mount the throttle detent and potentiometer, in various stages of assembly. |

|

The basic throttle mount. I made the detent lever from a piece of light-gauge stainless, with a brass bushing in the back and a nylon detent roller in the front. |

|

Detent lever fastened in place with a 3/32" spring roll pin. |

|

Here is the throttle detent assembly with detent wheel and potentiometer mounted to the collective. A single 3/32" spring steel roll pin fastens the detent wheel and the throttle and potentiometer shafts together. Two 10-32 stainless steel adjustment screws serve as hard mechanical stops for 1/8" spring steel roll pins on the side of the detent wheel. An aluminum lever connects the potentiometer case to the throttle mount and is also used for fine adjustment of the potentiometer. |

|

This is an aluminum cover I soldered together to protect all the mechanical parts and potentiometer from abuse and EMF. (Yes, they actually make a solder for aluminum. It is a zinc-aluminum alloy and it works very well! Here is one source, HTS-2000. Watch the video on their web site, you won't believe it until you see it.) |

|

Back side, with lock nuts on the 10-32 stainless steel stop screws. I'll use a little aluminum foil tape to cover the opening for the detent lever. |

|

Collective mounted in place. |

|

Full up. (It clears.) |

|

You can see where I reinforced the right side of the cross-tube a little. I did this before all the rest of the work above, because the copilot's collective was about 3/8" too far to the right and didn't line up very well with the seat pocket. I cut the cross-tube the proper distance left of the copilot's collective, flipped the copilot collective over and re-welded it to relocate the collective tube 3/8" further to the left. I then welded a sleeve around the cross-tube to reinforce the repaired area. |

Last Updated: November 10, 2003

|